Plastic Injection Mould Tools

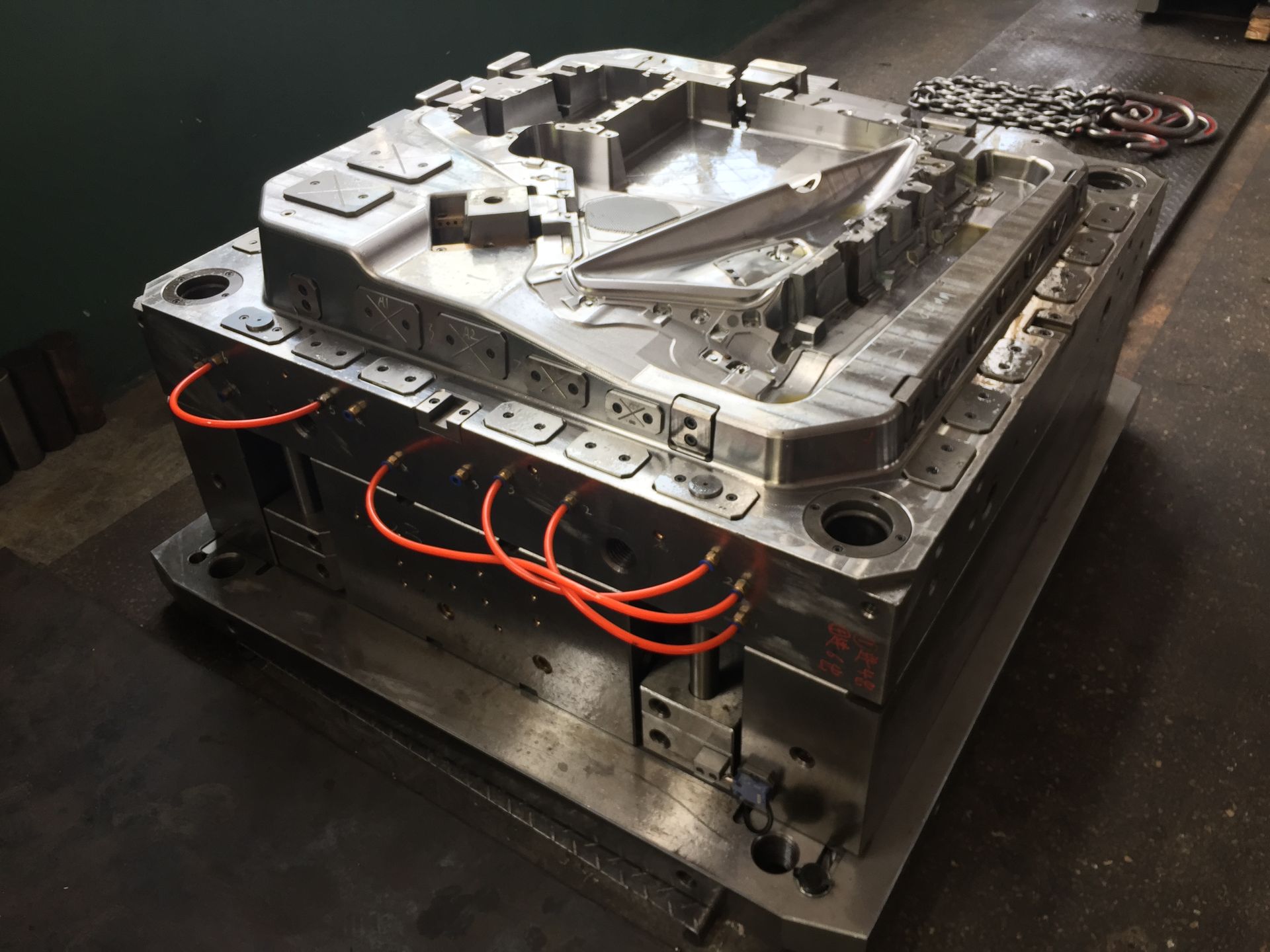

Production Tooling

Project management is key to the success of Plastic Injection Mould tool manufacture and we have developed procedures to ensure that each project runs smoothly, to specification and within schedule. The requirements of each customer are unique and to reflect this our tooling specifications are split into the following areas of quality:

Class 1 :

Rated for a minimum of 1 million cycles.

Built for high volume production made from high quality materials.

Class 2:

Rated for under 500,000 cycles.

Medium volume production mould. A popular mould for low to medium production needs.

Class 3 :

Rated for less than 500 cycles.

The least expensive mould for limited quantities or prototype parts.

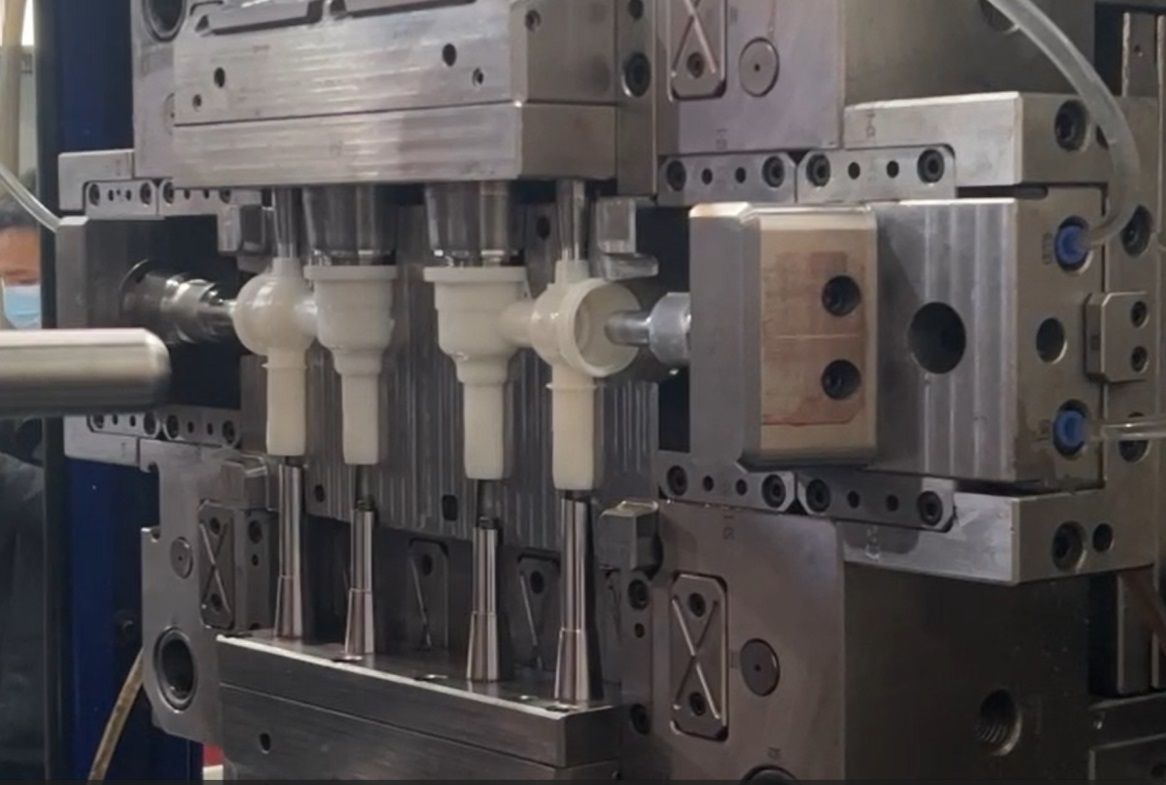

Process

As part of our standard process we check component cad data for mouldability. Any issues are highlighted along with our recommendations.

3D tool designs including DFM reports are issued electronically and if the parts are complex we will complete Moldflow analysis.

On design approval you will receive weekly schedules and photographs.

One of our UK Engineers will attend tool trials to monitor mould quality and debug if required.

UK tooling is delivered within days of approval and for off shore tooling we will import the moulds and manage all duties and taxes.

One of our UK Engineers we will attend installation trials at your facility or your chosen plastic moulding supplier.

Quality Tooling Completed on Time

Between 5 & 10 sets of parts are delivered for approval along with dimensional reports